Advantages 1. Environmental protection: replace the original refrigerant which has great harm to the environment with new environmental protection refrigerant, greatly reduce the damage to the atmospheric ozone layer, and eliminate the greenhouse effect

Advantage 2. Improve energy efficiency. Under the same refrigeration efficiency, its energy efficiency can be increased by more than 30% on average

Advantage 3: save energy, improve energy efficiency, reduce weight, and significantly reduce energy consumption

Advantage 4: reduce the cost. The volume can be reduced by more than 30%, the weight of materials can be reduced by about 50%, and the use of refrigerants can be reduced by more than 30%. Especially after replacing copper with aluminum, the price of aluminum with the same volume is only one twelfth of that of copper, and the manufacturing and use costs are greatly reduced.

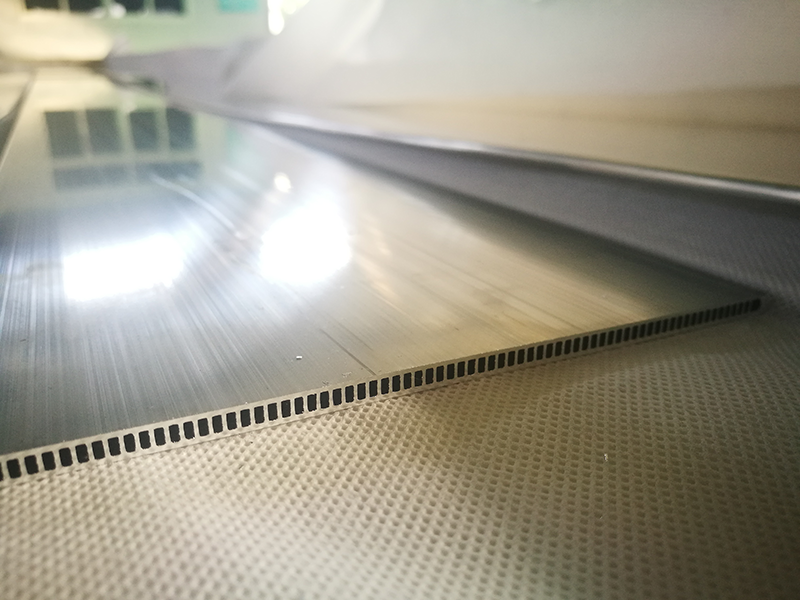

micro multiport extrusion tube specifications

| Items | Type | Range |

| 1 | Width | 8mm-40mm |

| 2 | Thickness | 1mm-5mm |

| 3 | wall thickness | 0.18mm-0.8mm |

| 4 | Thickness of zinc spray | 3g/mm2-20g/mm2 |

| 5 | Fixed length | 100mm-4000mm |

| 6 | Number of holes | 3-40 |

| Other non-standard sizes can be customized according to customer requirements. | ||