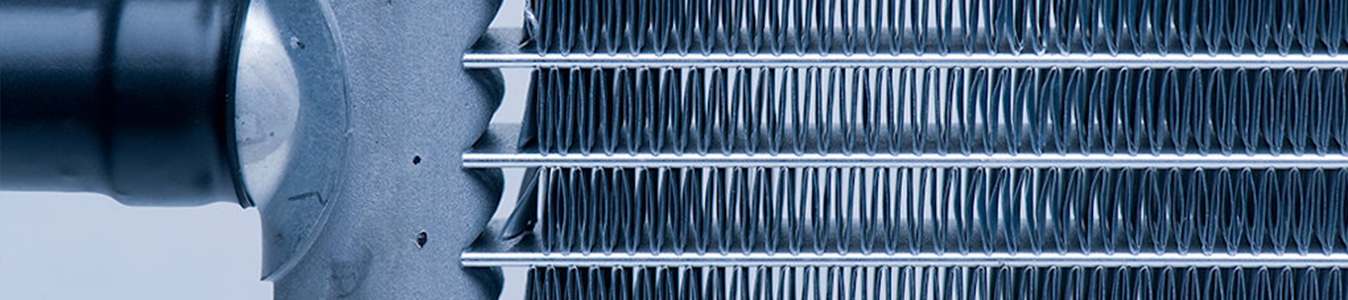

The radiator of automobile air conditioner consists of evaporator and condenser. The raw material of evaporator is mainly 8 * 1.0mm pure aluminum tube, and the raw material of condenser is mainly micro channel flat aluminum tube. Through experimental research, the product quality of domestic 8 * 1.0mm pure aluminum tube and micro channel aluminium tube has reached the use requirements;

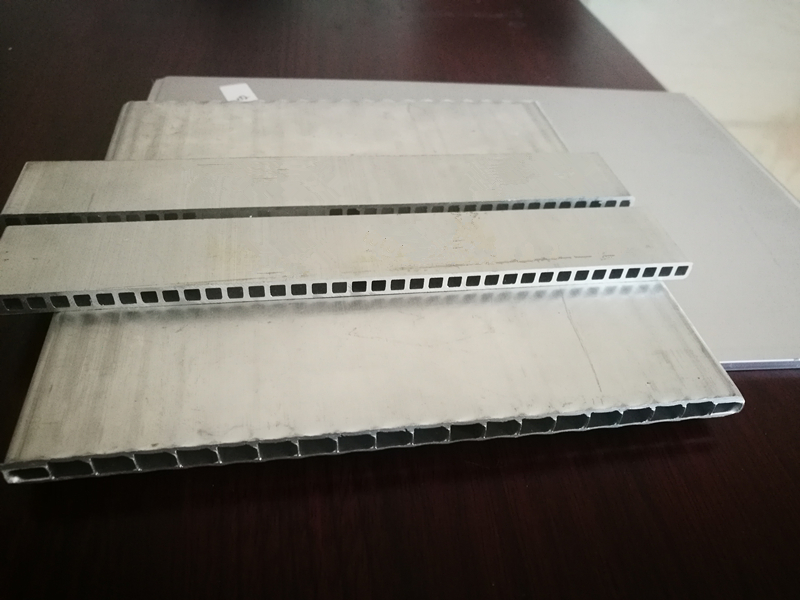

1. Requirements for the use of micro channel flat aluminum tube

The section of micro channel flat aluminum tube is similar to harmonica, so it is often called harmonica aluminum tube. In heat exchanger, micro channel flat aluminum Tube is used as a fluid conduit, and the tube is filled with cooling medium. Generally, the harmonica tube is designed as 5-25 holes, with a wall thickness of 0.6-0.8mm and a height of 5-6mm. The micro channel flat aluminum tube not only has a thin wall and many holes, but also is difficult to be formed during extrusion. Moreover, the channels are required to be relatively closed, the microstructure of the weld joint is free of defects, does not crack during cold deformation, and can bear a pressure greater than 8Mpa.

2. Material and specification of micro channel flat aluminum tube

The micro channel flat aluminum tube material should be aluminum alloy with good plasticity, strong fluidity, moderate strength, good welding performance and corrosion resistance. At present, most of the foreign countries use 1-series pure aluminum. We use 10501070 pure aluminum alloy,

3. Production process

The production process of micro channel flat aluminum tube: alloy smelting => casting =>sawing => heating => extrusion => tension straightening =v cut multiple scale => reshaping correction => cut length => inspection and acceptance => warehousing