micro channel aluminum tube MPE

News | 2020-04-02 17:59

Called "

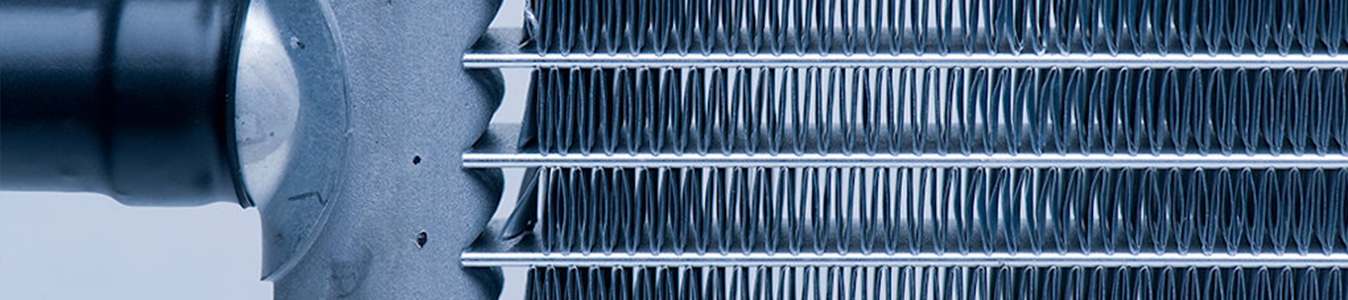

micro channel aluminum tube", all aluminum heat exchange coil was developed around 2008. At present, lvataand Delphi, the auto parts manufacturer, has begun to sell the heat exchange coil made of micro channel aluminum tube. Carrier and other manufacturers began to use the coil in air conditioning products. At present, Japan's major automotive air-conditioning manufacturers such as Denso and Sanden, as well as Chinese manufacturers such as Sanhua and Dunan, also begin to produce all aluminum heat exchange coil. The microchannel heat exchanger made of

microchannel aluminum tube has been used in the automotive industry for more than 20 years, and has only been used in the HVAC industry in recent years. The microchannel condenser coil is made of all aluminum brazed fins. The coil is divided into three parts: flat microchannel evaporative cooler is a common cooling equipment, and closed cooling tower is an application form of tubular evaporative cooler.

The main principle is that the spray water evaporates on the outer wall of the

micro channel aluminum tube to cool the fluid in the tube, and the water vapor generated is taken away by the fan in time to improve the cooling effect. Compared with the open cooling tower, the closed cooling tower avoids the direct contact between the cooling medium and the air, and the working medium in the pipe is not easy to be polluted. If the closed cooling tower is used in the conventional mechanical refrigeration air conditioning system, the cooling water and the cold water system can be switched in the transitional season, so as to realize free cooling and greatly save the operating cost of the refrigerator. Therefore, the closed cooling tower has a broad application prospect in energy saving of air conditioning.