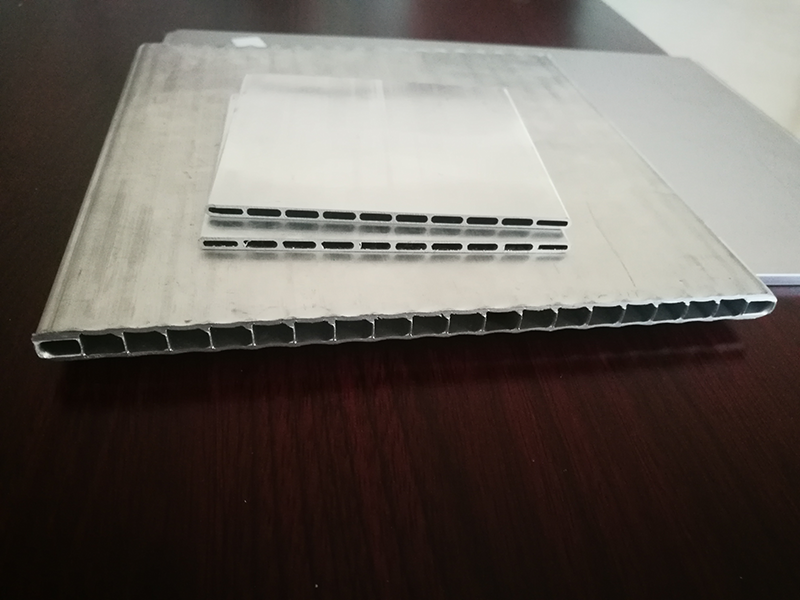

Due to the high technical content of micro aluminum square channel tube, the production is very difficult. The minimum width of the tube is 12mm, the thickness is only 1mm, but there are 12-16 holes. The difficulties are mainly reflected in the following six aspects:

1. Large extrusion ratio

Extrusion ratio refers to the ratio between the cross-sectional area before hot extrusion and that after extrusion, which is generally 8-50 times, while the sectional area of micro aluminum square channel tube is only about 4px2, and the extrusion ratio is more than 400 times, which is more than 8 times of aluminum extrusion limit process.

2. Ultra high dimensional accuracy

The dimensional accuracy of micro aluminum square channel tube is much higher than the national standard of "hot extrusion tube for aluminum and aluminum alloy research". According to the national standard, the width deviation of typical varieties is ± 0.3mm, while the width deviation of micro aluminum square channel tube is ± 0.03mm, which needs to be increased to ± 0.01 to ± 0.02mm.

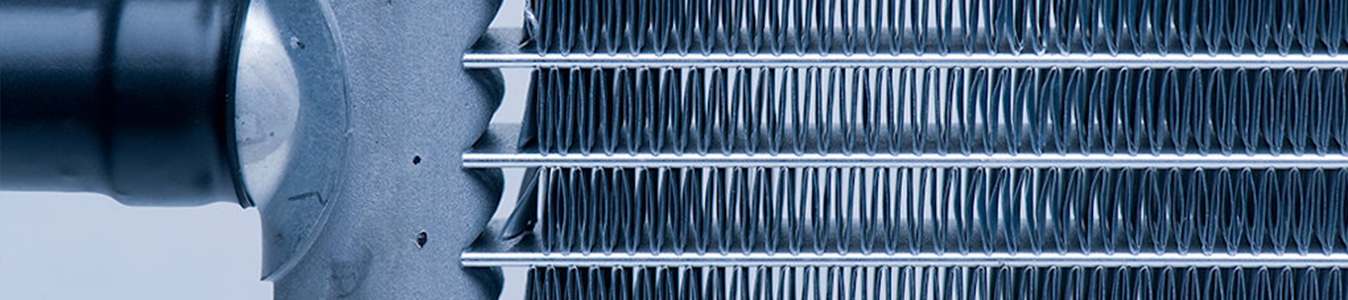

3. Air tightness

A set of microchannel heat exchanger has about 50-150 micro aluminum square channel tube. As long as one of them has air tightness defects (such as air holes, inclusions, etc.), the whole air conditioner will be scrapped. Therefore, the quality standard is calculated as ppm (1 million pieces), and the measurement standard is less than 15ppm.

4. High quality bar

The minimum limit wall thickness of micro aluminum square channel tube is only 0.13MM. If the purity and hydrogen content of the cast bar can not meet the requirements, as long as there is a very small pore or inclusion, the thin wall of the micro aluminum square channel tube will leak. Therefore, high purity refining rod must be used, with hydrogen content ≤ 0.09%.

5. Surface spraying zinc technology

Because of the refrigerant medium in the micro aluminum square channel tube and atmospheric corrosion outside, it is easy to cause leakage due to pitting corrosion. A thin layer of zinc must be sprayed on the outer surface of the tube to protect the tube wall from corrosion. Up to now, there is no qualified zinc spraying equipment manufacturer in China, and only a few manufacturers in the world can provide it.

6. Online flaw detection and detection technology

As the technology of micro aluminum square channel tube is very difficult and difficult, how to use scientific and effective on-line flaw detection, surface quality and other detection means in the production process to detect (mark) defective products in time is very important to the quality control of micro channel aluminum tube.