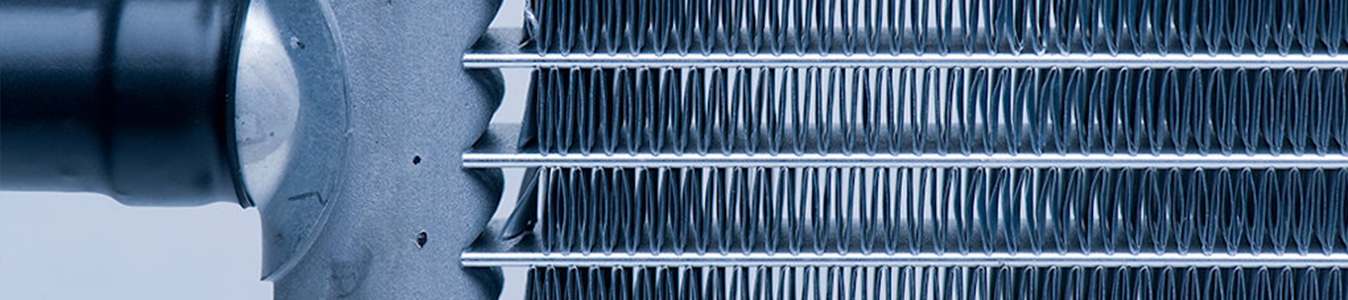

In recent years, scholars at home and abroad have done a lot of experiments and theoretical analysis on the phase change heat transfer microchannel. It is found that the fluid produces a series of complex flow and heat transfer behaviors in the microchannel with small water diameter, which greatly affects the heat transfer characteristics of the microchannel cooling aluminum tube, and proves that it has the heat transfer performance of high heat flow. This technology has a great prospect in the heat dissipation of electronic devices.

For the flow and heat transfer in the microchannel cooling aluminum tube with phase change, the flow and heat transfer of the microchannel cooling aluminum tube are mainly periodic subcooled flow boiling before reaching the critical heat flow density. The bubbles escaping from the microchannel cooling aluminum tube and the liquid entering the microchannel cooling aluminum tube wash the microchannel cooling aluminum tube back and forth. Once reaching the critical heat flow density, the microchannel cooling aluminum tube The flow and heat transfer in the microchannel will gradually evolve into a process of steam periodic escape, which will continue until the appearance of superheated steam, until finally the whole microchannel cooling aluminum tube is blocked by superheated steam, that is, when the microchannel cooling aluminum tube reaches the critical heat flow density, the steam will block the microchannel, and the microchannel cooling aluminum tube will dry up, leading to the failure of the microchannel cooling system.

Name: microchannel cooling aluminum tube

Surface treatment: silver white oxidation, black oxidation and other colored oxidation, spraying or customized according to customer requirements

Deep processing: sawing, filling with refrigerant, tapping, CNC milling, bending, grinding, deburring, etc;

Microchannel aluminum tube advantages:

1. Porous extrusion profile, the maximum width is 200mm, and the minimum wall thickness is 0.3mm.

2. Inject high-performance refrigerant for better heat dissipation.

3. The product has been tested continuously for 1000 hours, and the temperature difference remains stable within 3 ℃.

Application: this kind of heat pipe is suitable for all kinds of electronic products such as TV, laptop, led, etc