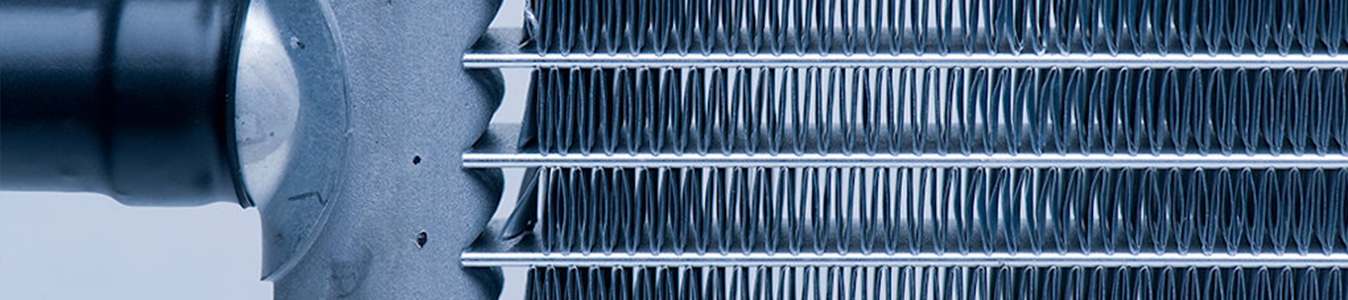

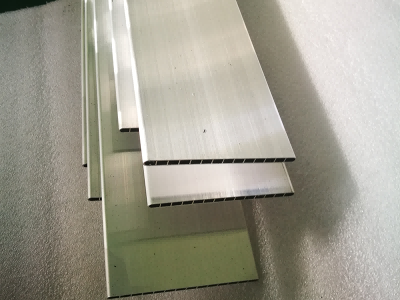

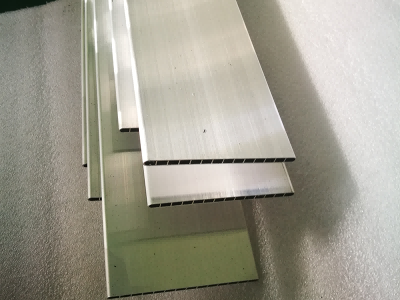

Micro channel zinc spray aluminum flat tube is a kind of micro channel aluminum tube (also known as "parallel flow aluminum flat tube") which is made of refined aluminum rod, hot extrusion and surface zinc spray anticorrosion treatment. It is a kind of thin-walled porous flat tube material and the key material of a new generation of parallel flow micro channel air conditioner heat exchanger.

The simultaneous interpreting and microchannel heat exchangers made of micro channel zinc coated aluminum flat tubes are mainly used in various air conditioning systems that adopt new environment-friendly refrigerants. As a new type of environmental protection refrigerant, the parallel flow microchannel heat exchanger is produced. Compared with the traditional copper tube and aluminum tube coil exchangers, the micro channel zinc aluminum flat tube has outstanding environmental protection, efficiency, energy saving and cost reduction.

The requirement of zinc coating on the surface of zinc spraying aluminum tube is high: the atomized particles are micron to submicron, and the requirement of zinc content per unit area is strict. International high-end products: for example, the micro channel zinc spraying aluminum tube used in automobile, commercial and household air conditioning heat exchanger is basically produced by hot extrusion! And the production method used is a large tonnage press (2200t-3600t in general) which uses a bar material (more than 100kg) as raw material to peel and extrude multiple microchannel aluminum tubes.

The simultaneous interpreting and microchannel heat exchangers made of micro channel zinc coated aluminum flat tubes are mainly used in various air conditioning systems that adopt new environment-friendly refrigerants. As a new type of environmental protection refrigerant, the parallel flow microchannel heat exchanger is produced. Compared with the traditional copper tube and aluminum tube coil exchangers, the micro channel zinc aluminum flat tube has outstanding environmental protection, efficiency, energy saving and cost reduction.

The requirement of zinc coating on the surface of zinc spraying aluminum tube is high: the atomized particles are micron to submicron, and the requirement of zinc content per unit area is strict. International high-end products: for example, the micro channel zinc spraying aluminum tube used in automobile, commercial and household air conditioning heat exchanger is basically produced by hot extrusion! And the production method used is a large tonnage press (2200t-3600t in general) which uses a bar material (more than 100kg) as raw material to peel and extrude multiple microchannel aluminum tubes.