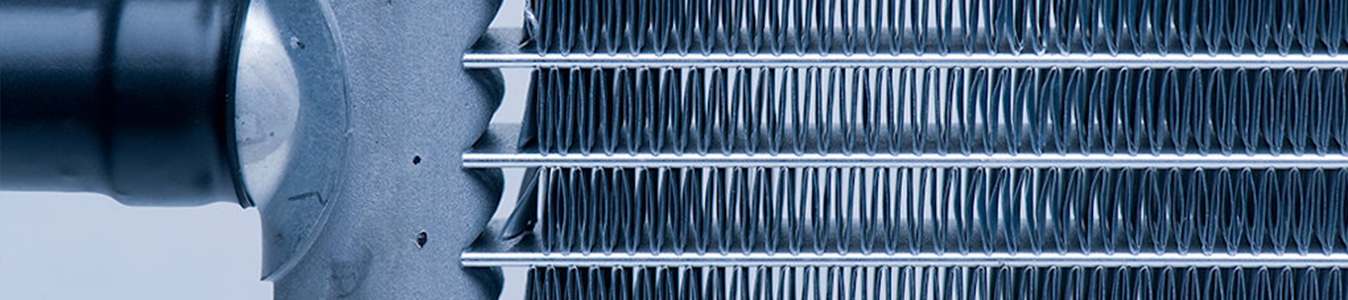

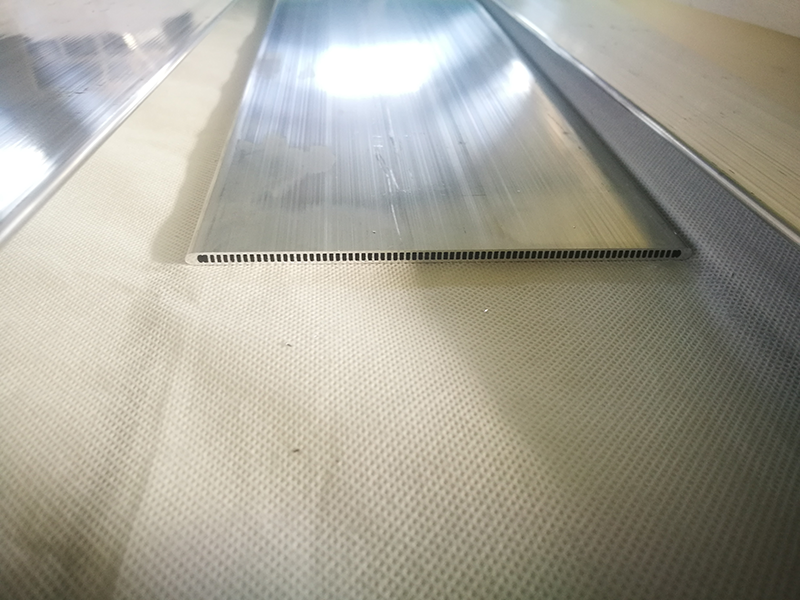

Micro channel cooling tube pipe can be divided into micro microchannel heat exchangers and large-scale Micro channel cooling tube pipe according to their overall dimensions.

Micro channel cooling tube pipe is a kind of compact, lightweight and efficient heat exchanger designed to meet the needs of the development of electronic industry. Its structural forms include flat cross flow Micro channel cooling tube pipe and sintered mesh porous Micro channel cooling tube pipe.

Large scale Micro channel cooling tube pipe is mainly used in traditional industrial refrigeration, waste heat utilization, automotive air conditioning, household air conditioning, heat pump water heater and so on. Its structural forms include parallel flow tube radiator and three-dimensional cross flow radiator. Due to its large size and the hydraulic diameter of microchannel is less than 0.6 ~ 1mm, it is called large-scale Micro channel cooling tube pipe. The large-scale production technology of forming microchannel in large-scale Micro channel cooling tube pipe is mainly limited by extrusion technology and pressure processing technology. The available materials are also very limited, mainly aluminum and aluminum alloy.

Application prospect of Micro channel cooling tube pipe:

① Application in microelectronics and other fields

The field of microelectronics follows Moore's law and develops rapidly. With the continuous improvement of transistor integration, the heat density of high-speed electronic devices has reached 5 ~ 10MW / m2. Heat dissipation has become the main "bottleneck" of its development. It has become an inevitable trend for Micro channel cooling tube pipe to replace traditional heat exchanger. Therefore,Micro channel cooling tube pipe will have broad application prospects in many fields such as aerospace, modern medical treatment, chemical and biological engineering and so on.

② Application of air conditioner and water heater

With the gradual maturity of Micro channel cooling tube pipe technology, automotive air conditioning industry and household air conditioning industry (such as Midea) have begun to produce related products. Fortunately, the hot air energy water heater industry has also begun to enter the microchannel field.

Application advantages of Micro channel cooling tube pipe:

① Energy saving. Energy saving is an important index of today's air conditioner. It is difficult for conventional heat exchangers to produce high-grade products such as class I energy efficiency standards. Micro channel cooling tube pipe will be the best choice to solve this problem.

②Outstanding heat exchange performance. In domestic air conditioning, when the channel size is less than 3mm, the law of gas-liquid two-phase flow and phase change heat transfer will be different from the conventional larger size. The smaller the channel is, the more obvious this size effect is. When the inner diameter of the tube is as small as 0.5 ~ 1mm, the convective heat transfer coefficient can increase by 50% ~ 100%. Applying this enhanced heat transfer technology to the air-conditioning heat exchanger and appropriately changing the structure, process and air side enhanced heat transfer measures of the heat exchanger are expected to effectively enhance the heat transfer of the air-conditioning heat exchanger and improve its energy-saving level.

③ Promotion potential. Micro channel cooling tube pipe technology has the potential to be popularized to air energy water heaters in the field of air conditioning manufacturing, which can greatly improve the competitiveness of products and the sustainable development ability of enterprises.

Compared with the conventional heat exchanger, the Micro channel cooling tube pipe not only has small volume and environmental protection performance, but also can meet the requirements of the domestic and foreign academic circles. It can not only meet the requirements of the conventional heat exchanger, but also has high pressure resistance and energy efficiency. The key technology of Micro channel cooling tube pipe - the production method of Micro channel cooling tube pipe has become more and more mature in China, which makes the large-scale use of Micro channel cooling tube pipe possible.