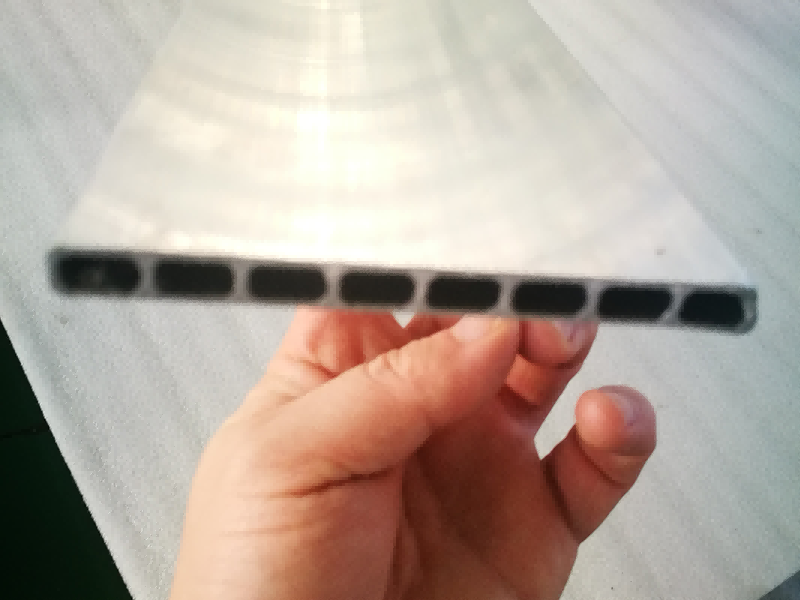

Alloy and specification

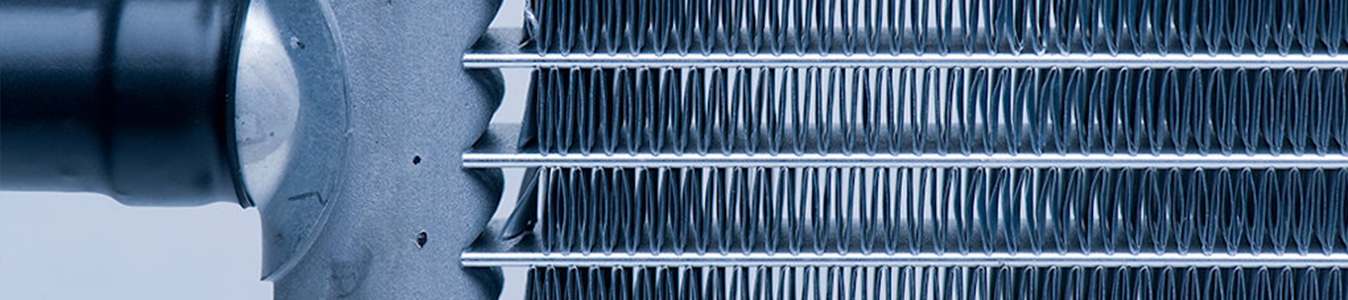

The Harmonica Shaped Aluminum Tube has thin wall, many holes and small inner cavity area. It should be extruded with alloy with good shaping, strong fluidity, moderate strength, good weldability and high corrosion resistance. Most of the first series of alloy are used. 1035 is used in China, The microstructure of 1050 and 1070 alloy, Harmonica Shaped Aluminum Tube weld shall be free of defects, and shall not crack during cold deformation. The bursting pressure that can bear is > = 8N / mm2. The processing plant uses 5-8mn extruder for extrusion. In order to improve the corrosion resistance of Harmonica Shaped Aluminum Tube, alloy 3003,3102 can be used, and Alloy 6063 can be used to improve the pressure bearing capacity of Harmonica Shaped Aluminum Tube.

Production process of Harmonica Shaped Aluminum Tube: smelting casting sawing heating extruding tension straightening multiple scale shaping correction cutting fixed scale inspection and acceptance warehousing delivery.