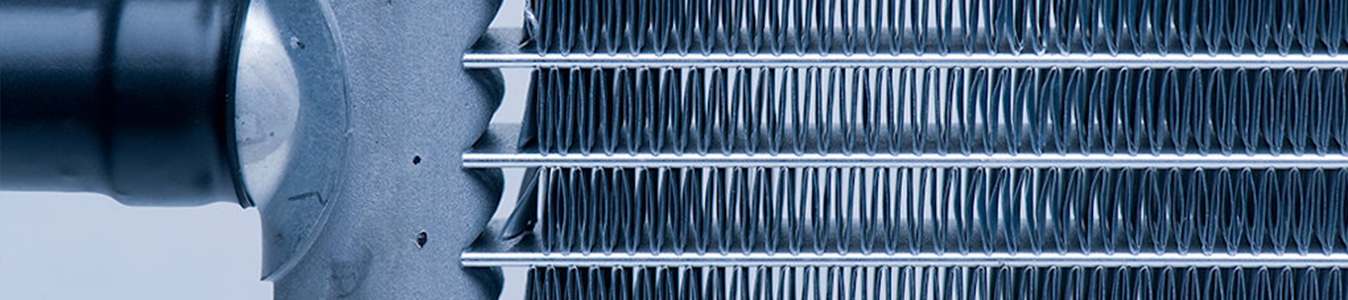

The specification of Galvanized aluminum parallel flow pipe:

| Alloy | 1100/3003/3102 |

| Temper | O H112 |

| Width | 8-150mm |

| Zinc coating thickness | 5g/mm2 -15g mm2 |

Galvanized aluminum parallel flow pipe has the following advantages:

1. the heat exchange efficiency between the refrigerant and the inner wall of the flat tube is increased by 40%, and the flow resistance of the refrigerant in the collector tube of the heat exchanger is reduced by 40%.

2. the fin heat exchange efficiency on the air side is increased by 40%, and the wind resistance of the air side heat exchanger is reduced by 40%.

3. the heat exchange performance of the whole heat exchanger is improved by 40%.

4. 40% less refrigerant than traditional technology.

5. comparison between all aluminum structure and copper aluminum structure: because there is no potential difference between copper and aluminum, the service life is longer.

6. the Galvanized aluminum parallel flow pipe can withstand the high pressure resistance limit of the existing refrigerant, with compact product structure, light unit weight, short process flow, high manufacturing reliability and relatively low cost.

Galvanized aluminum parallel flow pipe are widely used as heat exchangers for condensers, evaporators for automotive air conditioning systems, and radiators for engine cooling systems.