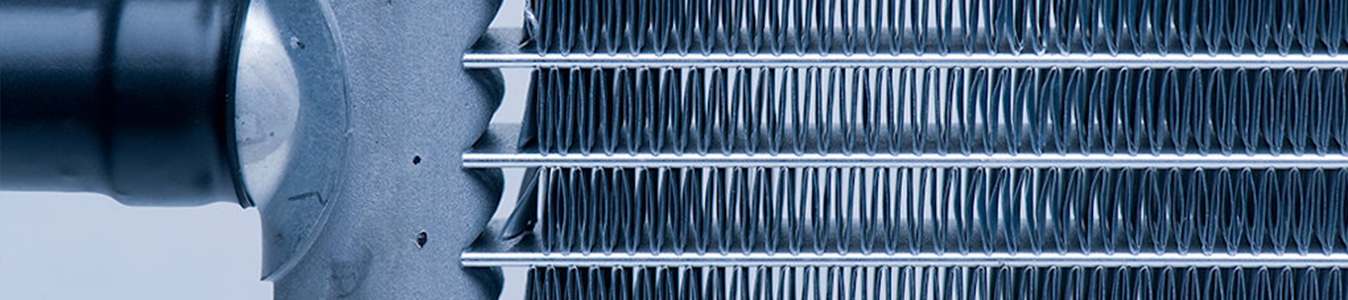

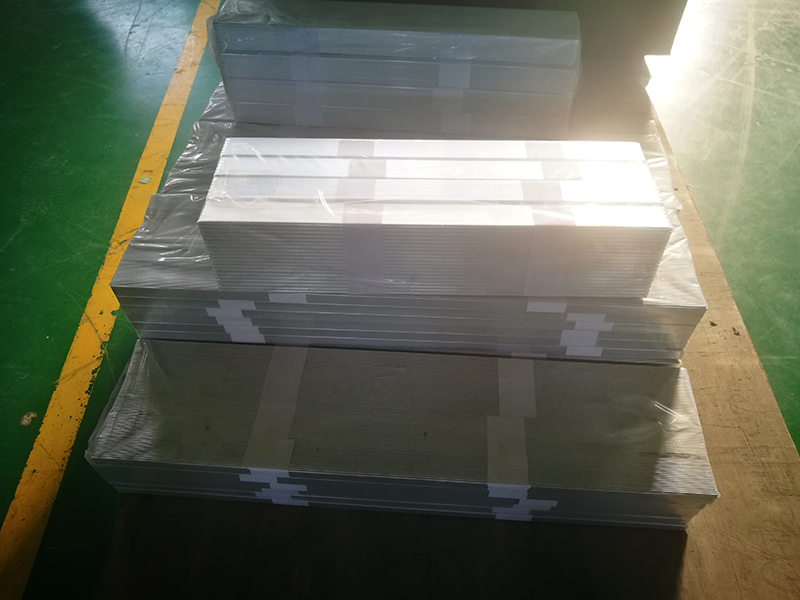

Aluminum precision tubing for heat exchange, which is used for evaporator and condenser and belongs to the forming part of operation class. Aluminum precision tubing for heat exchange is characterized in that it is made of aluminum or aluminum alloy, and the flat pipe is separated into 4 ~ 22 holes by vertical stiffeners, which increases the contact surface between the pipe wall and the fluid in the pipe, and accelerates the heat conduction.

Advantage of Aluminum precision tubing for heat exchange:

1, heat conduction surface expansion, good heat dissipation;

2, the weight of copper heat exchanger flat tube reduced by two thirds;

3, the cost is half of the copper heat exchange flat tube;

4, high compressive strength.