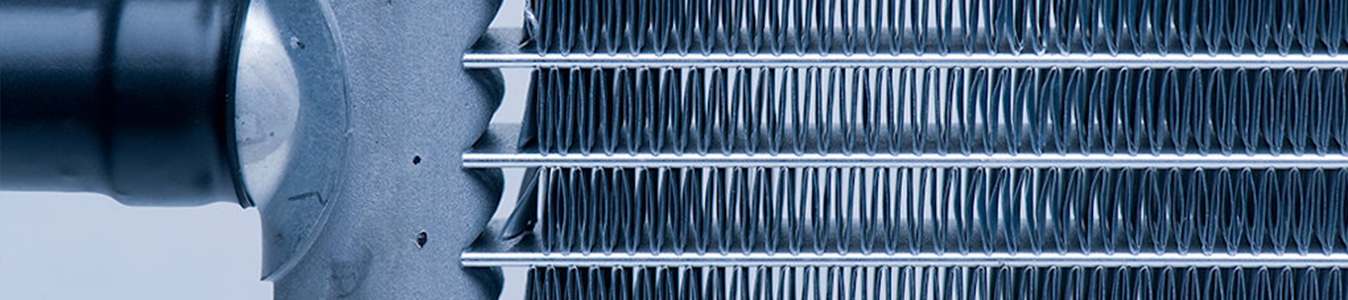

The particularity of Aluminum parallel flow tube tubes

1. Super large extrusion ratio

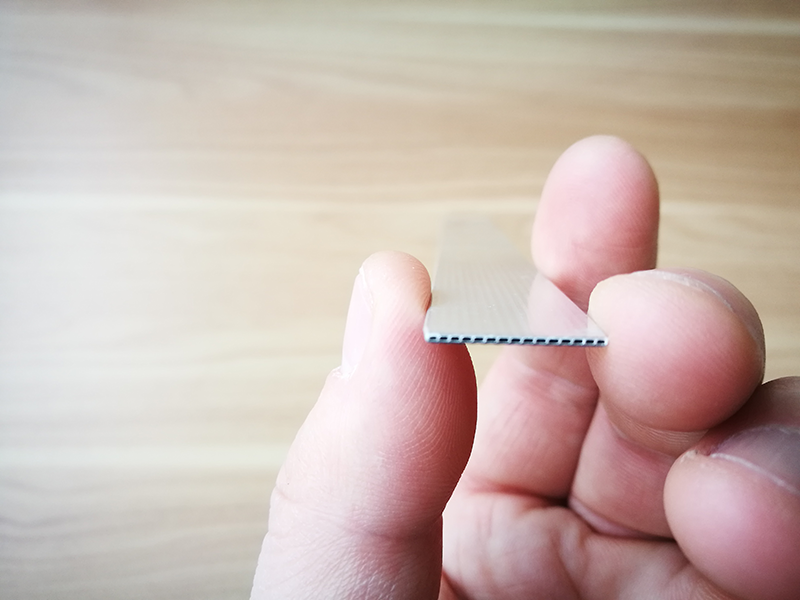

Aluminum parallel flow tube tubes is one of the smallest section of aluminum alloy pipe at present, the section area is about 0.16cm2, must be a hot extrusion way extrusion molding, and the extrusion ratio to reach more than 400 times.This brings about technical problems of extrusion ratio, which have very high technical requirements for process control, heating temperature difference, mold feed port, feed passage, welding cavity, sizing belt design and cooling in the working process.

2, ultra-high dimensional accuracy

The dimensional accuracy of Aluminum parallel flow tube tubes is much higher than that of conventional hot extrusion products.It is difficult for ordinary aluminum alloy profile factory to reach this standard.

3, air tightness

The Aluminum parallel flow tube tubes products produced by a casting rod have a length of nearly 500 meters. In the extrusion process, the production process must be guaranteed to be absolutely stable and reliable. A small deviation in one link will lead to defects in the product.

4, high quality casting rod requirements

The wall thickness of the Aluminum parallel flow tube tubes is only 0.16-0.35mm. If the purity and hydrogen content of the casting rod are not up to the requirements, as long as there are tiny pores or impurities, the thin wall of the Aluminum parallel flow tube tubes will leak.

5. Surface treatment requirements

Due to the very precise requirements of Aluminum parallel flow tube tubes, the combination interface of zinc spraying layer on the surface is required to be very high, leading to only a few companies' zinc spraying equipment can be used for zinc spraying of flat pipe.