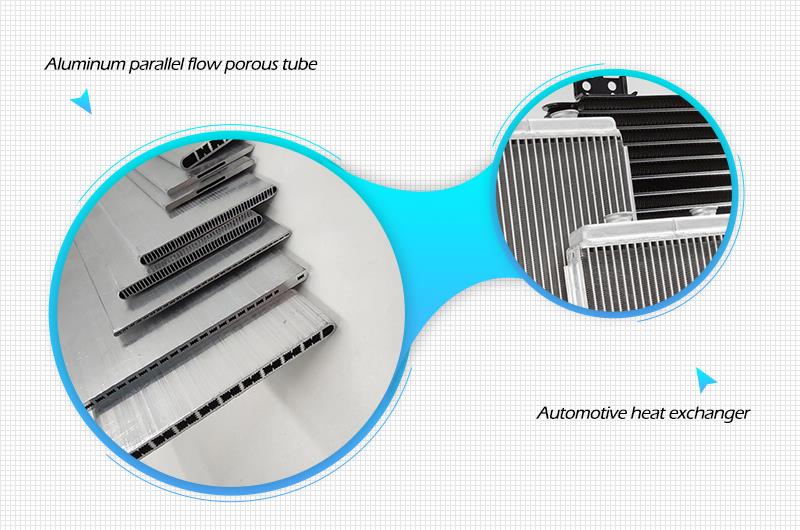

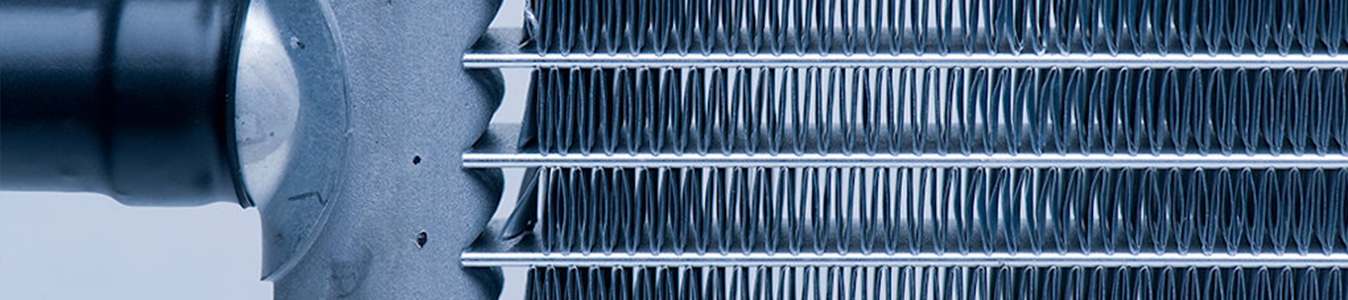

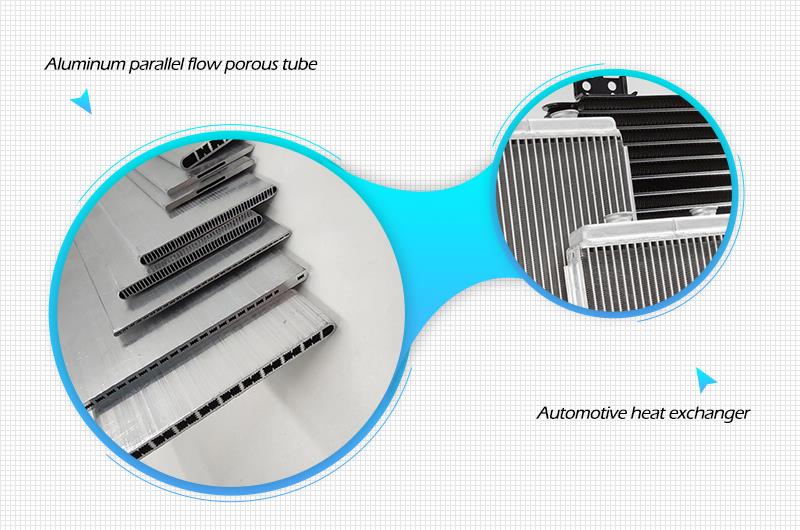

With the rapid development of automobile industry, the evaporator and condenser for automobile heat exchanger no longer adopt the segment structure made of copper tube and aluminum foil, but adopt the

Aluminum parallel flow porous tube and aluminum composite foil. They have the advantages of small volume, light weight and good heat exchange performance.

Aluminum parallel flow porous tube is the key material of all aluminum microchannel heat exchanger. With the environmental protection and high efficiency of refrigerant in automobile air conditioning system, the pressure resistance requirements of

Aluminum parallel flow porous tube will be higher and higher. The adoption of a new generation of pollution-free CO2 refrigerant puts forward higher requirements for the pressure resistance of parallel flow tube. Under the condition of equal wall thickness, the bursting pressure will be increased from 8Mpa to more than 12MPa, but the

Aluminum parallel flow porous tube currently used is in weight, pressure resistance The durability is not particularly ideal, and the extrusion production of

Aluminum parallel flow porous tube is difficult due to complex section shape, thin wall, large number of holes and high dimensional accuracy .

Chalco aluminum is an excellent factory in producing a

Aluminum parallel flow tube, so it can provide various

Aluminum parallel flow porous tube with different sizes, shapes, aluminium alloy.

Chalco's technology is at the leading level in China, with mature production process, stable production process, high production efficiency, stable product quality and high safety.

Application: the scientific and technological achievement has obtained the national invention patent, and the technical product can be used in the microchannel heat exchanger of various air conditioning systems.