Production Process

1,The six technical features of our company's production of micro-channel aluminum flat tubes:

1),High-quality cast rod: our micro-channel flat tube aluminum rod filter 40 mesh + 0.09 ~ 0.13, but generally 20 mesh + 0.2

2),High requirements for zinc spraying: the amount of zinc layer is 6-8g / ㎡, but the general spraying fluctuations are large

3),Online Flaw Detection: Requires Online Flaw Detection

4),Large extrusion ratio: our extrusion ratio is greater than 427, which is more than 8 times higher than conventional extrusion ratio (50)

5),Ultra-high dimensional accuracy: The accuracy requirement is ± 0.03, which is more than 8 times higher than the international high-precision level

6),High air tightness requirements: Product defects are measured by PPM, which is 200 times higher than traditional% requirements

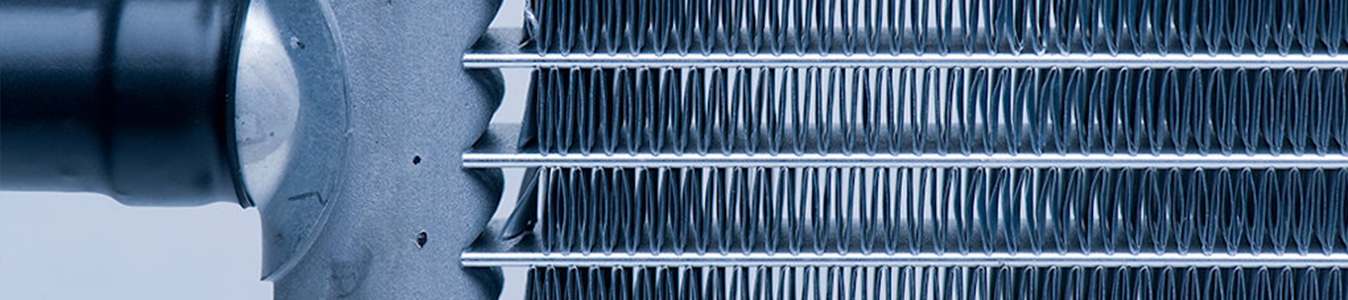

2, The main production process of micro-channel aluminum flat tube:

Aluminum rod heating extrusion --- zinc spraying --- rewinding --- flaw detection --- reshaping& cutting --- inspection packaging

-Aluminum-rod.png)

1)-Aluminum rod

-Aluminum-rod-heating-extrusion.png)

2)-Aluminum rod heating extrusion

-zinc-spraying-1.png)

-zinc-spraying-2.png)

-zinc-spraying-3.png)

3)-zinc spraying 1,2,3

-rewinding-1.png)

-rewinding-2.png)

4)-rewinding 1,2

-flaw-detection.png)

5)-flaw detection

-reshaping&-cutting--1.png)

-reshaping&-cutting--2.png)

6)-reshaping& cutting 1,2

--inspection-packaging-1.png)

--inspection-packaging-2.png)

7)- inspection packaging1,2