1,The Introduction of 1100 Parallel Flow Aluminum Tube

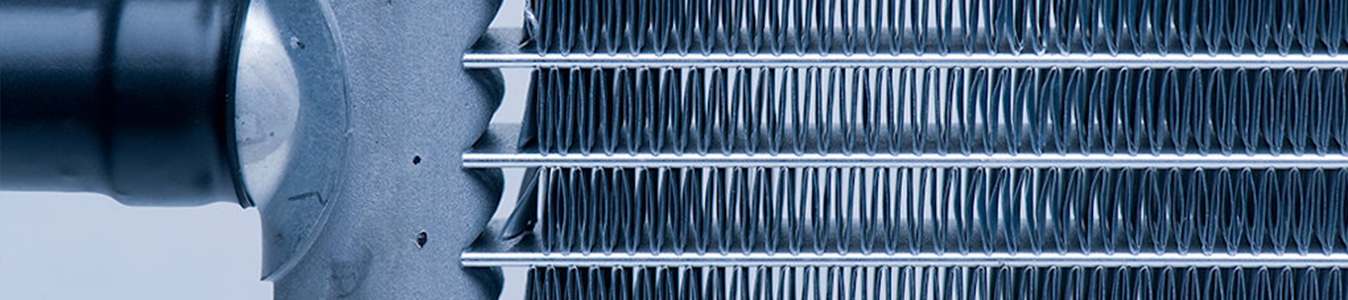

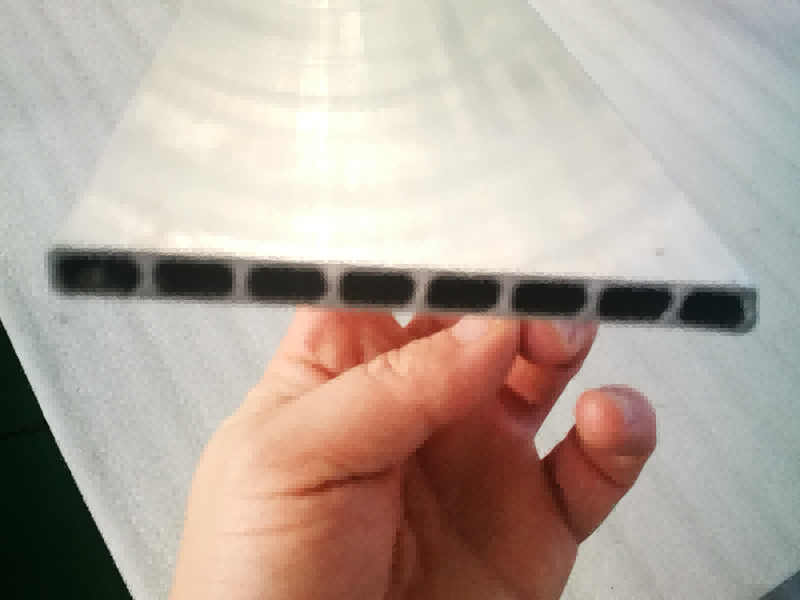

1100 aluminum is used to produce porous micro-channel aluminum flat tubes because of its good ductility, formability, weldability and corrosion resistance; Using of the refined 1100 aluminum rods, going through of Hot extrusion, and zinc sprayed on the surface,so as to produce out of 1100 Parallel Flow Aluminum Tube, which are mainly used in various refrigerant air-conditioning systems as pipe parts carrying new environmentally friendly refrigerants, are the key materials for the new generation of parallel-flow micro-channel air-conditioning heat exchangers.

2.The Specifications of 1100 Parallel Flow Aluminum Tube

The specific specifications are as follows:

1) Alloy: 1100

2) Temper: O / F / H111 / H112

3) Width: 6mm-240mm

4) Height: Above 0.8mm

5) Wall thickness:Above 0.12mm

6) Number of Ports: 2-75 Ports or according to customer drawing requirements

7) Delivery status: Coiled Flat Tubes or cut into different lengths according to customer requirements.

Length: 50-6000mm

8) The Specifications of Coiled aluminum flat tube:

Reel inner diameter: 400-550mm, etc.

Reel outer diameter: 700-1500mm, etc.

Reel height / width: 300-1000mm, etc.

Zinc layer weight: 6-8g / ㎡ or according to customer requirements

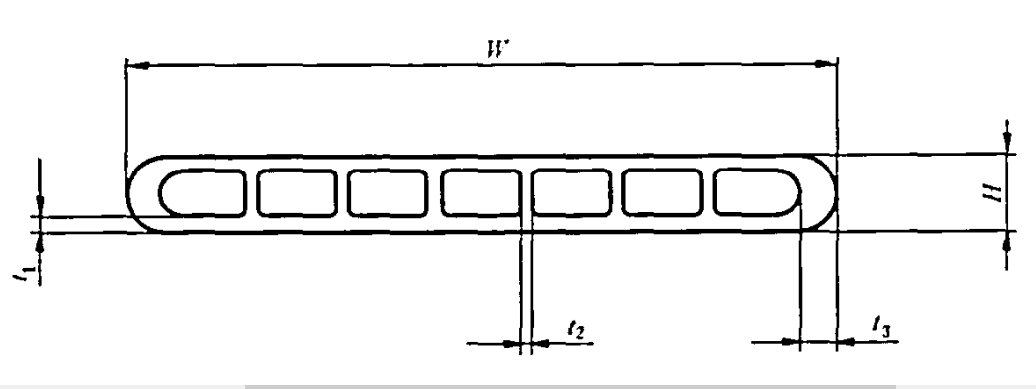

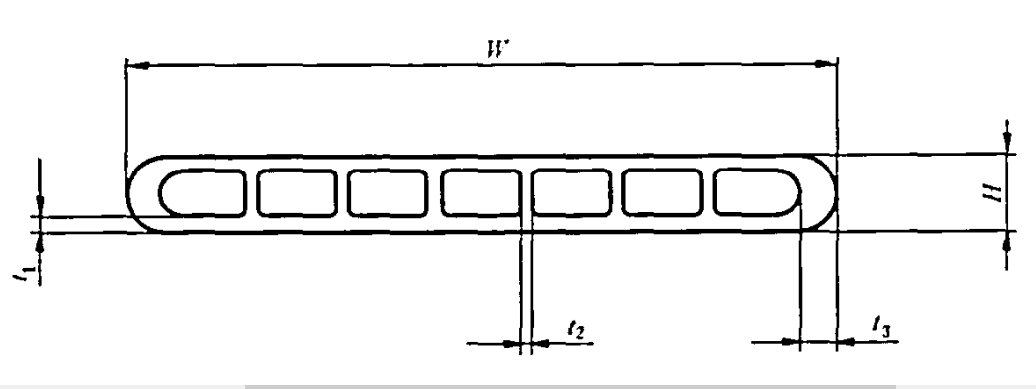

9) The product specification deviations see as below (The cross-sectional views see as below):

10)The chemical composition of 1100 Parallel Flow Aluminum Tube is as follows:

11)The mechanical properties of 1100 Parallel Flow Aluminum Tube in room temperature are as follows

12)The Pressure resistance of 1100 Parallel Flow Aluminum Tube

For flat tubes of water (oil) medium heat exchangers for automobile air conditioners, household or commercial air conditioners, and other purposes, the burst pressure should meet the requirements of the table below. When the purchaser has special requirements or the product is used for other purposes, the supplier and buyer can negotiate to determine the burst pressure.

3,The Product features of 1100 Parallel Flow Aluminum Tube

1) The 1100 Parallel Flow Aluminum Tube is light in weight and has good thermal conductivity and electrical conductivity

2) 1100 Parallel Flow Aluminum Tube has good corrosion resistance

3) 1100 Parallel Flow Aluminum Tube has good ductility, formability and weldability

4) 1100 Parallel Flow Aluminum Tube has high recycling value

5) The 1100 Parallel Flow Aluminum Tube produced by our company has a small deviation range and high surface quality.

4,The Product application of 1100 Parallel Flow Aluminum Tube

The 1100 Parallel Flow Aluminum Tube is widely used in the home appliance refrigeration, refrigerator freezer, vehicle refrigeration, base station cooling, industrial refrigeration, etc fields, and is specifically used in condensers and evaporators with high requirements for automotive air conditioners and civil air conditioners

5. The current product drawings of 1100 Parallel Flow Aluminum Tube can be downloaded from product drawing. DOWNLOAD !

1100 aluminum is used to produce porous micro-channel aluminum flat tubes because of its good ductility, formability, weldability and corrosion resistance; Using of the refined 1100 aluminum rods, going through of Hot extrusion, and zinc sprayed on the surface,so as to produce out of 1100 Parallel Flow Aluminum Tube, which are mainly used in various refrigerant air-conditioning systems as pipe parts carrying new environmentally friendly refrigerants, are the key materials for the new generation of parallel-flow micro-channel air-conditioning heat exchangers.

2.The Specifications of 1100 Parallel Flow Aluminum Tube

The specific specifications are as follows:

1) Alloy: 1100

2) Temper: O / F / H111 / H112

3) Width: 6mm-240mm

4) Height: Above 0.8mm

5) Wall thickness:Above 0.12mm

6) Number of Ports: 2-75 Ports or according to customer drawing requirements

7) Delivery status: Coiled Flat Tubes or cut into different lengths according to customer requirements.

Length: 50-6000mm

8) The Specifications of Coiled aluminum flat tube:

Reel inner diameter: 400-550mm, etc.

Reel outer diameter: 700-1500mm, etc.

Reel height / width: 300-1000mm, etc.

Zinc layer weight: 6-8g / ㎡ or according to customer requirements

9) The product specification deviations see as below (The cross-sectional views see as below):

| The deviation of Product specification | |

|

Specification W(Width) x H(Height)x L(Length) |

Allowable deviation (mm) |

| W(Width) :6mm-240mm | ± 0.2mm max |

| H(Height):Above 0.8mm | ± 0.1mm max |

|

Plane wall thickness t1:Above 0.12mm |

± 0.1mm max |

| Support thickness: t2 | ± 0.1mm max |

| Side end wall thickness:t3 | ± 0.1mm max |

| L(Length)≤1000mm | ± 0.5mm |

| L(Length) >1000-2000mm | ± 1.5mm |

| L(Length) >2000- 6000mm | ± 2.0mm |

| Flatness | ≤0.2mm |

| Curvature(Every 300mm length) | ≤0.3mm |

| Curvature(Full length on L meter) | ≤1.0 x L(mm) |

|

Twisting degree (Full length on L meter) L ≤ 1 |

≤1.0 x L(mm) |

|

Twisting degree(Full length on L meter) L > 1 |

≤1.0 (mm) |

| Note: The deviation range of product specifications can also be controlled according to customer requirements | |

10)The chemical composition of 1100 Parallel Flow Aluminum Tube is as follows:

| Alloy | Chemical component(%) | ||||||||||||

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Ni | Other | Al | |||

| Each | Total | ||||||||||||

| 1100 | Si+Fe≤0.95 | 0.05-0.20 | ≤0.05 | - | - | ≤0.10 | - | - | ≤0.05 | ≤0.15 | 99.00 | ||

11)The mechanical properties of 1100 Parallel Flow Aluminum Tube in room temperature are as follows

| Alloy | Temper |

Tensile Strength Rm MPa |

Yield Strength Rp0.2 MPa |

Elongation A50mm % |

| not less than | ||||

| 1100 | H112 | 75 | 20 | 20 |

12)The Pressure resistance of 1100 Parallel Flow Aluminum Tube

For flat tubes of water (oil) medium heat exchangers for automobile air conditioners, household or commercial air conditioners, and other purposes, the burst pressure should meet the requirements of the table below. When the purchaser has special requirements or the product is used for other purposes, the supplier and buyer can negotiate to determine the burst pressure.

| Bursting pressure Unit:MPa | ||||

| Automotive air conditioner heat exchanger | Household or commercial air-conditioning heat exchangers | Water (oil) medium heat exchangers for other purposes | ||

| Non-electric vehicle | Electric car | |||

| Condenser | Evaporator | |||

| ≥11.5 | ≥5.5 | ≥11.5 | ≥16.5 | ≥14.5 |

3,The Product features of 1100 Parallel Flow Aluminum Tube

1) The 1100 Parallel Flow Aluminum Tube is light in weight and has good thermal conductivity and electrical conductivity

2) 1100 Parallel Flow Aluminum Tube has good corrosion resistance

3) 1100 Parallel Flow Aluminum Tube has good ductility, formability and weldability

4) 1100 Parallel Flow Aluminum Tube has high recycling value

5) The 1100 Parallel Flow Aluminum Tube produced by our company has a small deviation range and high surface quality.

4,The Product application of 1100 Parallel Flow Aluminum Tube

The 1100 Parallel Flow Aluminum Tube is widely used in the home appliance refrigeration, refrigerator freezer, vehicle refrigeration, base station cooling, industrial refrigeration, etc fields, and is specifically used in condensers and evaporators with high requirements for automotive air conditioners and civil air conditioners

5. The current product drawings of 1100 Parallel Flow Aluminum Tube can be downloaded from product drawing. DOWNLOAD !