Who we are

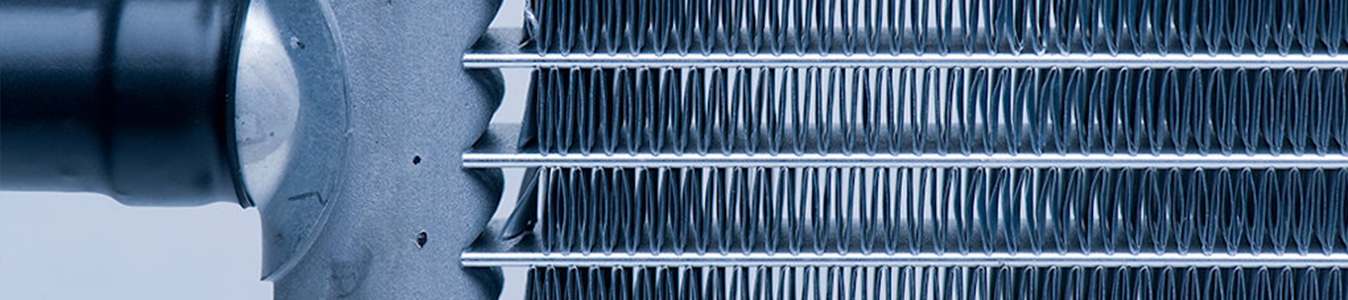

Chalco Aluminum has 39 fabrication facilities in China, 4 plants mainly

typically produce aluminium plate, sheet, coil, foil, extrusions, rod, bar,

tube, forge stock, and wire.

Rolled plate sheet plant is located in Xin'an Country of Luoyang city in

Henan, total area of about 400000 square meters, the existing staff of 760

people. The enterprise comprehensive competitiveness in the country ranks in the

forefront of the same type of business, is the best quality, yield the largest

high-grade cap with high-grade anodized Aluminum Alloy cold-rolled strip, 1

series and 3 series Aluminum Alloy for cold rolled strip production base. Our

company with high precision aluminum foil project investment 1 billion yuan,

started construction in June 2002, trial production by the end of 2003, March

2005 completed and put into production, now has an annual output of 100 thousand

tons of high precision aluminum foil production capacity. The leading products

are hot 8011 closure sheet, 8 series foil stock, 5 series plate coil, anodizing

purpose aluminum coil sheet etc, the products are widely used in many fields of

aviation, automobile, building decoration, household appliances, packaging,

electronic information etc.

High quality plate and extrusion plant located in Harbin city Heilongjiang

provice, the plant mainly produces aluminum, magnesium and its alloy plate,

belt, foil, pipe, bar, type, line, powder material, forgings and other products,

the products are widely used in aerospace, weapons, ships, petrochemicals,

transportation, electronic industry and other areas of the national economy, and

exported to Europe and the United States, Japan, South Korea, Southeast Asia

etc. countries and regions. In more than and 60 years, the company created

Chinese aluminum processing history numerous first, provide a large number of

light alloy materials for the "Shenzhou spacecraft" series of

spacecraft and the "Chang-E" and other key projects, has made

important contribution to the start and development of our aerospace, defense

and military career.

Industry aluminum extrusion plant located in Longxi City Gansu province, leading

products for aluminum and aluminum alloy tubes, rods, bar, various industrial

aluminum extrusion products, the products are widely used in aviation,

aerospace, weapons, nuclear industry, national defense science and technology,

transportation, machinery manufacturing, instrumentation, home appliances,

chemicals, electronics, electricity, construction, packaging, decoration and

other industries. In order to meet the special needs of the industry and

military materials, the plant investment to build a Aluminum Alloy extrusion

production line of special materials, has been completed and put into

production, the plant become high level security base of national defense

materials, have important influence in the country, providing a strong support

platform for scientific research and development and production of military

products.

Aluminium forging product plant located in Chongqing city, the main products are

aluminum and aluminum alloy die forgings, free forging, die casting,

high-temperature alloy and other products. After 50 years of construction and

development, this plant become China's most comprehensive strength of large

aluminum processing enterprises, is the core base of China Aerospace and defense

industry materials.

Chalco Aluminum

Difference

1. Quality Certification

In the course of the Company's operation, certified management systems are

applied such as the quality management standard ISO 9001:2008 and the

environmental management standard ISO 14001:2004, staff healthy and safety

management standard OHSAS 18001:2007,

The Company issues certificates for the compliance of all aluminium products

with the European Union standard.

For materials regarding food (foodstock, canstock) all the specifications that

ensure the safety and hygiene of the products, which will finally come into

contact with food, are strictly followed. The specifications are set in

accordance with international standards and in co-operation with our customers,

in order to satisfy the specific requirements of each end-receiver. Adherence to

these safety regulations is ensured by inspections, carried out both by the

in-house auditors, as well as by the customers themselves, at regular

intervals.

At the same time, the production sections which handle food-related materials,

have implemented the HACCP system using risk analysis, while crucial checkpoints

have been set, for the prevention and elimination of risks that may affect the

safety of those materials.

2. Continuous Improvement Process (CIP)

The CIP scheme is an integral element of the corporate philosophy within the

Chalco Aluminum. The aim of CIP is to tap into the specific experiences and

individual creativity of every single employee. All processes, particularly

those which relate to product development, manufacturing and sales, are

constantly assessed in the search for possible improvements in terms of quality,

costs and time as well as the avoidance of waste. Of course, the human element

is also assigned a high priority since improvements in relation to safety in the

workplace and working conditions overall are also important aspects of the CIP

process.

The CIP organization within the Chalco Aluminum is based on efficient teams.

These are supported by functionaries and bodies such as the CIP Moderator, CIP

Coordinator and CIP Steering Committee. Continually advising all employees about

the work, experiences and results associated with CIP activities is a key

requirement for the sustained success of the process. This is achieved by means

of various communication channels and instruments such as notice boards,

Intranet, regular newsletters and CIP events based on a standardised reporting

format which facilitates concise and easy-to understand information about the

CIP activities of the individual teams. All suggested improvements are collected

and processed in a central database that can be accessed by all staff.

Administrators ensure that the suggestions are evaluated systematically, process

the suggestions, and handle the payment of bonuses.

CIP is:

Company culture

Problem solving technique

Office-CIP

Focus-CIP

Project-CIP

Idea management

Mill-CIP

6 S (to bring workplaces in a safe, clean, uncluttered and ergonomic

state)

Visualization

CIP-Groupwork

3. Center of Excellence

Chalco Aluminum’s engineers, designers and metallurgists, along with our

sales personnel, work collaboratively with customers to develop innovative

products and alloys for a myriad of applications. Our engineering experts in our

“Center of Excellence” located at Luoyang facility use process

development equipment for casting, extrusion, forging and rolling to address the

most taxing design and manufacturing challenges.

All these processes are supported by analytical tools such as scanning electron

microscopy and advanced CAD/CAM systems. Alloy development is another research

area where Chalco Aluminum is expanding the possibilities, whether the objective

is in making more corrosion resistant products or increasing weldability and

strength.

4. In case of claim

In case of any discrepancies with regards to quantity and quality, the Buyer has to lodge the complaint within 30 days after the date of receiving goods at discharging port. In the event of the complaint found genuine, the buyer have to present enough photos and videos as seller's request, the Seller shall settle this claim within the next 30 days by remitting the agreed compensation amount. If the packing have problem because of rude loading and unloading, please claim to insurance company directly.

Corporate values

At Chalco Aluminum, we manage our business

for long-term success in a manner that is economically, environmentally and

socially responsible. We demonstrate this through operating our business

with honesty and integrity, providing a safe workplace environment that

fosters dignity and respect, creating a positive economic impact for our

stakeholders, supporting the sustainability of the environment and striving

to make a positive difference in our local communities.

Chalco Aluminum’s commitment is

built on the following values:

Governance

We are committed to clear, honest and

respectful engagement with our stakeholders within a culture of

accountability, responsibility and ethical behavior. We are committed to

complying with legal and regulatory requirements wherever we operate and

fostering positive relationships with governments and regulatory

agencies.

Fair Business Practices

We are committed to fair business practices

and to treating our employees, customers and suppliers with dignity and

respect.

Health & Safety and the

Environment

We are committed to protecting the health

and safety of our employees and to supporting the sustainability of the

environment.

Sustainable Value Creation

We strive to have a sustainable economic

impact on our stakeholders by providing attractive returns to shareholders,

creating opportunities for our employees, fostering innovation and

continuous improvement in our products and operations and engaging our

customers in the process to ensure we deliver quality products and

“Best in Class” customer service.

Community Development and

Engagement

We engage in our communities through

employee volunteer activities, community outreach, education and local

partnership programs.

History

1. Henan Chalco Aluminum Fabrication Co.,Ltd set up at August 12th

2005

Main machine equipment

2400mm width Hot Roughing Mill + double coiler hot finishing mill unit 1

set;

2400mm single stand double coiler 1 unit;

2050mm cold rolling machine 3 sets;

2300mm cold rolling mill (imported equipment) 1 set;

2. Luoyang hot rolled plant, and Luo yang Cold rolled plant set up at

Jun 2006

Main machine equipment

2000mm cold rolling mill 1 set;

1850mm cold rolling mill 1 set;

1450mm cold rolling mill 1 set;

1400mm cold rolling mill 1 set;

2000mm aluminum foil mill 4 sets,

50 thousand tons of casting production line.

3. Henan Chalco was ertified to the environmental management standard

ISO 14001:2004 and staff healthy and safety management standard OHSAS

18001:2007 at Nov. 21th 2013

4. Henan Chalco was Certified to the quality management standard ISO

9001:2008 at Jan. 15th 2014

5. Henan Chalco Zhengzhou office set up at National HI-Tech Industry

Development Zone, Zhengzhou end of Oct. 2016, in charge for Chalco Aluminum

products exporting---- aluminum rolled plate sheet, coil, strip, foil;

aluminum industrial extrusion product; aluminum forging product; aluminum

wire etc.